Why Manufacturers Need Contract Technology Amid Supply Chain Disruptions

Contract management technology gives manufacturers of all sizes more agility.

Geopolitical turmoil is prolonging supply chain disruptions, and nearly half of the procurement leaders surveyed in a recent poll expect the market shakeup to last until late 2023. Inflation, a possible recession, pandemic-related shutdowns and logjams at ports aren’t making the situation any easier.

Manufacturers are taking a variety of approaches to counter this instability, including:

Sourcing: move from a sole source to multi-source model to diversify the vendor network

Negotiation: leverage stocking agreements to help reduce price variation

Pricing: raise prices, which is always a last resort, since it makes a company less competitive and punishes consumers

Larger manufacturers have been able to navigate instability—and minimize negative side effects like price increases—by employing a combination of tactics. Many smaller manufacturers have fewer options, generating a great deal of uncertainty. All manufacturers are looking for other viable options.

Contract management tech gives manufacturers of all sizes more agility

Relying on legacy systems within the supply chain cycle that are not compatible with today’s modern technologies creates a lack of visibility that makes it difficult to plan ahead or respond quickly to changing market dynamics. Today’s manufacturers must be agile, regardless of size or the supply chain and operational strategies they employ. They need to be able to respond in real time to the changing global supply chain and political environment.

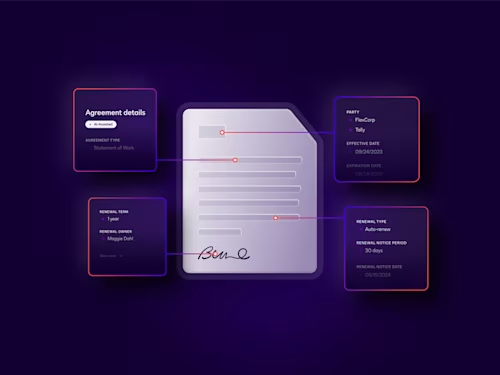

Contract management technology is one tool that augments each of the approaches above, and can often be the difference between surviving and thriving.

Contracts can either play a big role in addressing instability or be a big barrier to executing quickly. Regardless of which approach a manufacturer takes to manage the impact of supply chain disruption, digital contracts are a critical tool to help operate more efficiently and effectively, providing the agility to respond to changes as they happen.

Here are a few critical ways digital contract management can help manufacturers get ahead:

Onboard vendors faster: In many industries, onboarding is already tedious and may include going through pre-production processes like fit samples, lab dips, mold creations and rigorous QA. The ability to generate, execute and act on contracts in days instead of weeks or months is a big competitive advantage.

Update master service agreements (MSAs): Negotiating MSAs can be difficult with redlines going back and forth. Digital contracts significantly speed up this process.

Feel confident in big changes: Making major changes to the supply chain involves a lot of people and complex contracts. Using digital workflows and routing automates much of the paperwork involved, so every detail is visible to legal, operations, finance, sourcing and other departments to get work done more quickly.

Eliminate errors: The ability to require fields ensures busy executives don’t forget to provide required information. It also eliminates the need to go through contracts multiple times because of errors, incomplete information or change requests.

As you develop your supply chain strategy in today’s ever-changing geopolitical climate, contract management is a must-have tool that’s easy for companies of all sizes to implement.

Improving supplier relationships with new systems

Companies such as Fuji Xerox Australia (FXA) have attested to the role Docusign played in improving supplier relationships. Prior to working with Docusign, it relied on paper-driven processes to onboard vendors and manage supplier relationships. The procurement team was constrained by having to print, sign, scan and manually send contracts. This was cumbersome for everyone and resulted in unnecessary delays.

By implementing Docusign eSignature with PowerForms, FXA’s procurement team has streamlined document execution for master services agreements, statements of work, ordering documents and supplier onboarding forms. The use case was extended to payment approval forms as well given the efficiency of such processes.

“The feedback from staff has been fantastic,” said Marcus Bracken, head of procurement for FXA. “Docusign was easy and quick to set up. There was no cumbersome process required to get up and running, and the training provided for additional features is online and self-explanatory.”

Learn more

For more information, check out the following resources:

Manage Supply Chain Disruptions with Contract Technology for Procurement

How AI Helps Companies Identify Force Majeure Clauses in Contracts

If you’re ready to take advantage of the benefits of digital contract management, contact sales to learn more.

Related posts

Docusign IAM is the agreement platform your business needs